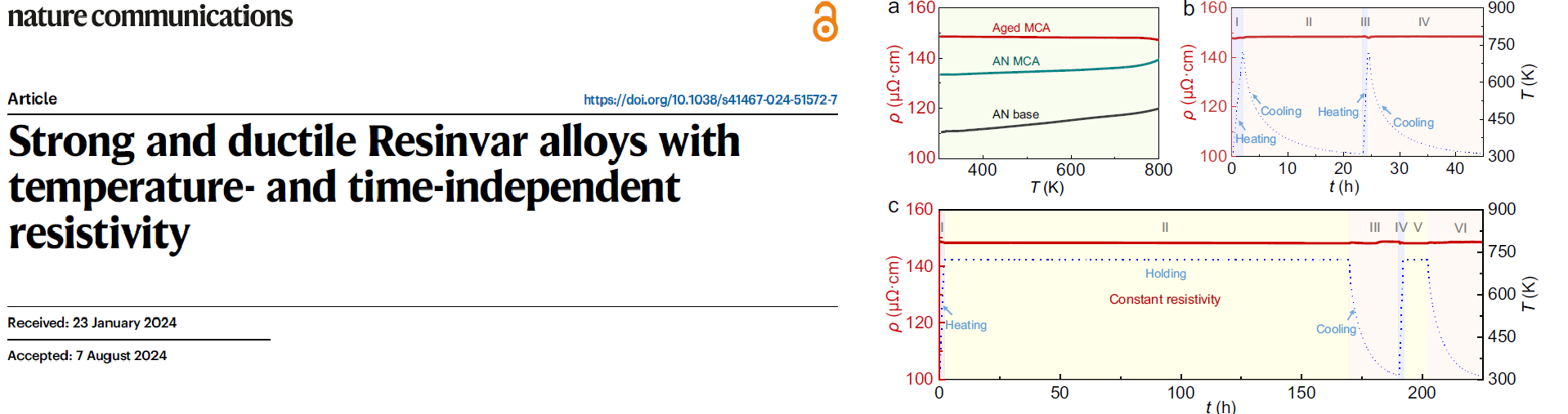

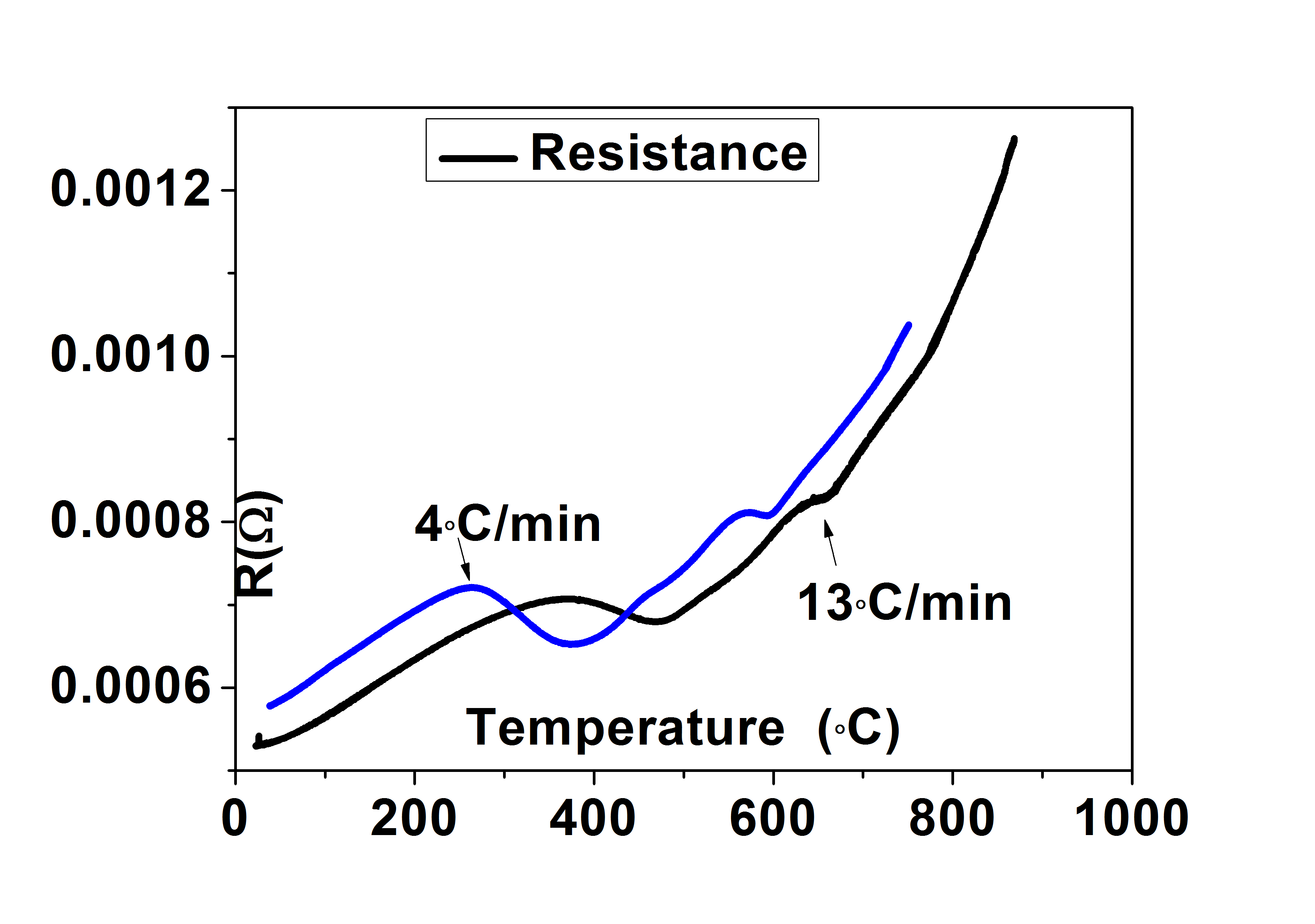

The characterization of microstructural changes during the heat treatment process of copper alloys provides key information for the study of microstructure and properties. In the figure, there are resistance peaks near 300 ℃ and 600 ℃ that are related to the heating rate. The peak temperature increases with the heating rate, which is consistent with the basic mechanism of material phase transition characteristics. The temperature corresponding to the two resistance peaks in this heat treatment process is related to the precipitation of alloy solid solution and is also an important parameter for regulating the electrical resistivity of copper alloys. Japanese scholars have attempted to calibrate the tempering precipitation temperature of similar alloys using DSC method, but the endothermic/exothermic effect of precipitation is not significant. Therefore, the resistance temperature characteristics of alloys is an important method for characterizing copper alloy phase transition process during heat treatment processes.

Contact:(086)13338002060 (Engineer Zhang); QQ:2429337838;Email:jinfeng.zhang@sipcc.com.cn